Bob, in response to your invitation to comment on the passive house you are designing for us, here are some thoughts.

I see this first of all as an opportunity to be part of the solution instead of part of the problem. The chance to show off the kind of technology and design choices that--were they widely adopted--could significantly reduce reliance on fossil fuels feels not just like an opportunity to showcase your talents as an architect but to participate in a necessary new way of thinking about housing. That you are, coincidentally, our son-in-law certainly plays a role in our enthusiasm, but it goes so far beyond providing for immediate family and grandchildren. It goes to realizing the models that are going to keep the earth inhabitable for everyone's grandchildren.

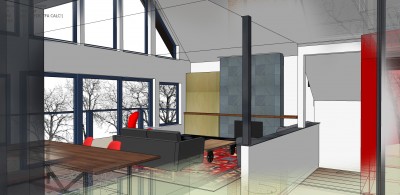

Coming back to the ground now, to the very immediate house in question and the very personal responses on an aesthetic and emotional level: It's exciting to think about having a space designed to support who we are and how we like to occupy space. The openness of most of the design, combined with the privacy of spaces designated for bedroom and in-home offices for each of us, is perfect. I imagine fondly the day when, if one of us is cooking in the kitchen and the other is in the living room, we won't have to shout to each other to be heard. I look forward to having a cup of tea by the floor-to-ceiling south-facing windows. Visual access to the outside year-round is crucial to my mental health, and if I have a view of the outside space, I need far less inside space. I am inordinately pleased by the idea that we may be able to design a root cellar into this house. The idea of storing garden vegetables connects the seasons for me. (An aside: I got a ridiculous amount of pleasure in Seattle from picking kiwi fruit in October/November, and eating it in December, January, and even February.) And, of course, those floor-to-ceiling south-facing windows will be a great spot for starting plants in the winter and early spring. Did I say I love the idea of floor-to-ceiling south-facing windows?

We love wood fires, but I've got to admit that each time I build one these days and notice the ash that has to be cleaned out and the wood dust on the rug that will need to be vacuumed I realize these are tasks I will not miss. And again, as we age, and things tend to take a little more time to accomplish just because of increased physical limitations, I won't regret leaving wood and ash hauling behind. It will leave more time for reading and writing. In the cozy office spaces or by the wonderful floor-to-ceiling windows.

Then there’s air quality and noise issues. I’m given to respiratory irritations and ailments, which means that, especially during heating season, I keep a HEPA filter running in the living room and a humidifier in the bedroom. Both are noisy, but help to create a white noise effect that drowns out traffic on the street outside. I know I’m going to enjoy the quiet of a super-insulated house and the climate-controlled clean air I’ll be breathing.

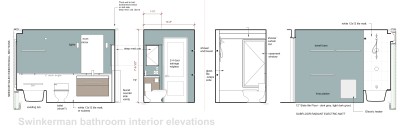

As we are very near retirement age, it pleases me that we're designing this house to be one in which we can age. Thinking ahead not to the inevitability but the possibility of one or the other of us needing a wheelchair at some point, and having the first floor bathroom at the ready, means not having to worry about retrofitting in a hurry someday.

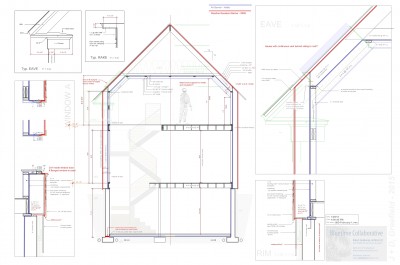

Just knowing some of the principles of Passive House design has made me so much more aware of heat and cold. I take a hot bath, and imagine the system that will capture the heat as the water cools. I open the curtains when the sun is shining, the better to capture a bit of the free solar warmth. I have begun to use the term "thermal bridging" in casual conversation.

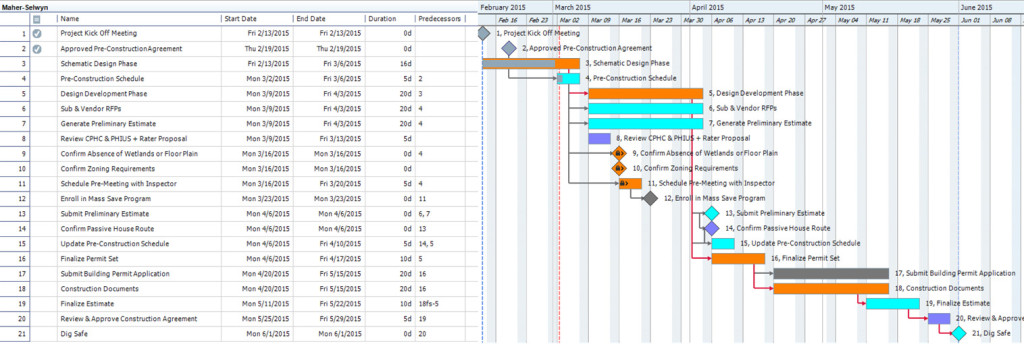

Circling back to the overview: I like that we are able to support, with this project, not only the concept of Passive House but also the business model that you, Mel, and Chad are using. Having presided over a remodel in Seattle, I need no convincing that it's going to be worth it to have project coordination and scheduling built in to the process and the services your team is going to provide us.