I am grappling with window issues for several projects right now. Designing, choosing, pricing and detailing windows is much more complicated than it was as recently as 5 years ago. I used to simply specify window sizes and the builder would have the lumber yard price a few lines or a favorite manufacturer. This is still the way it is done my most builders and architects. Now we have many more options to consider with windows and this has radically affected the decision making process. In the past we didn’t look carefully at the solar gain (how much warmth from the sun gets in, visible light transmittance, U value (insulation) and especially installation detailing. With my own work, a primary goal has become to eliminate the traditional heat distribution system – boiler (oil, propane or natural gas) manifold (that thicket of valves and pipes and pumps in the basement) and distribution (radiant tubes in the floor, baseboard radiators etc) – in favor of the simplicity of an air source heat pump and often, a wood stove for alternate or backup heating. The heating system then becomes a heating appliance. This has not, for my practice, been a client driven goal but I figure I’m not doing my job if I don’t discuss these options. Most clients in recent years have simply expressed a desire to minimize fossil fuel consumption and have a house that they don’t have to worry about leaving for a few weeks in the winter. Windows are usually the biggest variable in being able to minimize and simplify the heating equipment for a building.

The process, which continues to evolve, begins with sizing and placing windows according to light, views, privacy and ventilation. So far, a fairly traditional approach. Some things effect the decisions such as whether the window opens inward, outward, up and down, sideways, or not at all. Smaller windows open easier and larger fixed pane windows are cheaper (per square foot) so we often mix and match for maximum effect. Exterior doors are often now part of the window package as well.

I use sketchup modeling for this part of design as it brings a high level of clarity at an earlier stage than any method I’ve found thus far. This is also not so traditional.

Once we have arrived at a good window configuration we need to pin down some minimum energy performance specifications. The first big decision is double glazed vs triple glazed. Double glazed windows meet energy code currently but probably won’t in a few years. Window manufacturers (in the US – in Europe they are already there) are starting to realize this and gear up to offer triple glazed window options. A largish house with small windows can probably get away with double glazed windows and meet the energy use criteria I mentioned above. I also have found that with large areas of glass, comfort becomes a big issue. It can be very unpleasant to be near a large window at night when it is zero degrees outside. Condensation issues are vastly mitigated with a triple glazed window as well. I often do some energy modeling to get a sense of what the overall heat loads of the building are. It's easy to change around the U-value to see the effect of different windows. I'm also learning how to use the sketchup plugin for the Passive House Planning Package. In my spare time. (insert smiley emoticon)

Next we look at several different options from several different window manufacturers. Unplasticized PVC (UPVC) is usually the least expensive option for any window with aluminum and fiberglass usually more expensive but offering thinner profile frames. Wood is very expensive. I’ll stay away from the PVC argument here.

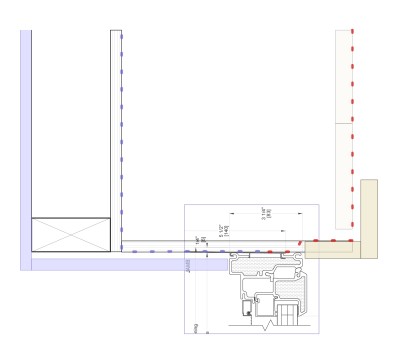

With preliminary pricing in hand we – myself, the builder and the client make THE DECISION and the subset of choices that affect the price and my detailing. When these decisions are made I can put specific CAD details from the manufacturer into my drawings and create much more accurate details for how it all the windows are installed, air sealing strategies, tolerances, finish work around the windows, very specific rough opening and flashing information etc. In the past this was all fairly standard and left to the builder to figure out in the field. We don’t do it that way anymore.